TANKS FOR OIL STORAGE

Tanks suitable for the storage of the oils used for the production of Margarine, Shortening and Ghee as: RBD Palm Oil, Palm Olein, RBD palm Stearin, Soybean oil, Sunflower oil, Rapeseed oil, etc.

Capacity of each tank from 10 to 100 tons.

FEATURES

| • |

Structure in stainless steel AISI 304 (both parts in contact with the product and the insulation jacket) with conical bottom resting on feet |

| • |

Heating circuit (to keep the oil at the desired temperature) |

| • |

Total insulation to minimize heat loss to the external environment. |

| • |

Accessories for operation as: valves, probes, filters, stirrers, etc.. |

| • |

Connection for nitrogen inlet in order to prevent oil oxidation and contamination |

The tanks can be supplied with electrical control panel and control with PLC-PC

The tanks are provided as a single piece (Shipping Container 40 'box) up to 25 tons, otherwise in container-fitting pieces assembled and welded on site by EBM personnel.

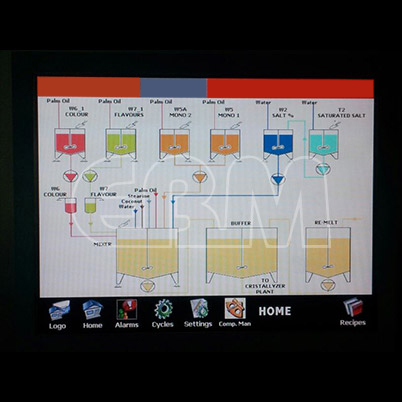

MIXING TANKS AND INGREDIENT DOSAGE

Tanks suitable for the mixing and dosing of water, oil, additives, vitamins, etc. required by recipes in order to obtain Margarine, Shortening and Ghee as for production specifications. Capacity of each tank ranging from 100 to 3,000 liters depending on the hourly production of the production line.

FEATURES

| • |

Structure and construction in stainless steel AISI 304 and /or 316 for the parts in contact with the product with conical bottom resting on feet. |

| • |

Heating circuit (to keep the oil at the desired temperature) |

| • |

Totally jacketed to minimize heat loss to ambient, the insulation coating is on AISI 304 stainless steel fully welded. |

| • |

Accessories for operation as: valves, sensors, filters, agitators, transfer pumps, tri-blender, load cells and so on. |

The tanks can be supplied with electrical control panel and control with PLC-PC

The tanks are supplied mounted on a stainless steel AISI 304 pre-assembled containerized skids.

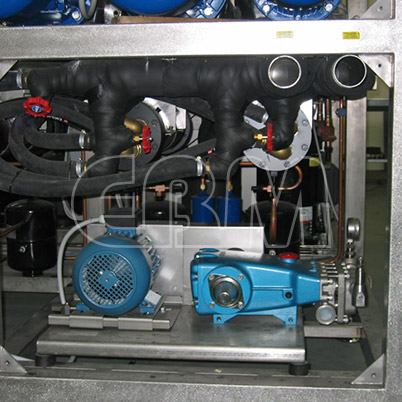

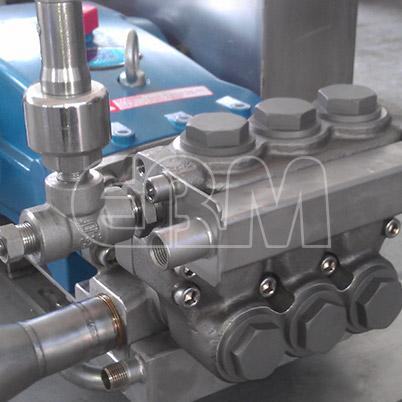

HIGH PRESSURE PISTON PUMPS

Suitable pumps to consistently feed the Coimix® machines and packaging systems with suitable pressures in the production process.

If required, the pumps can be supplied with:

| • |

AISI 316 stainless steel filter (to prevent foreign objects inside the blends from damaging the pump), easy to open for cleaning and maintenance. |

| • |

Automatic nitrogen distributor system. Nitrogen is injected at piston pump intake. |

Pressure range of EBM pumps is from 0 to more than100 bar.

FEATURES

| • |

Electric motor / pump support structure in stainless steel AISI 304 complete with casing and resting on shock absorbers |

| • |

Hot water heating circuit for pump head |

| • |

Pump case in stainless steel AISI 316L |

| • |

Accessories for operation such as: safety valves for high pressure, pressure gauges, etc. |

| • |

Connectors for nitrogen injection in the process |

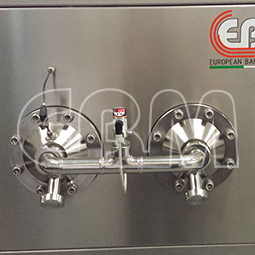

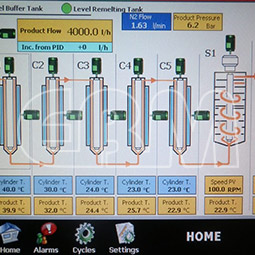

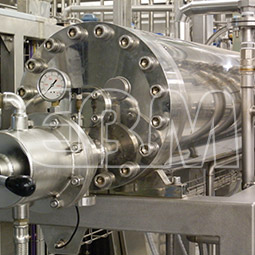

COIMIX® MACHINES (SSHE - SCRAPED SURFACE HEAT EXCHANGER)

The COIMIX® machine is suitable to crystallize vegetable and animal fats and different types of emulsions. The various margarines and shortenings carry a different behavior during the crystallization phase as a function of their nature and composition. The rotors of the crystallizers are equipped with floating blades made of special stainless steel.

The COIMIX® is complete with refrigeration compressors, one for each of crystallization tube and is very versatile due to a high cooling efficiency and reduced energy consumption. Furthermore, each crystallizer tube has an automatic defrosting system to optimize waiting times and formulation changes.

It is able to produce Table Margarine, Puff Pastry Margarine, Cake Margarine, Shortening, Ghee or Vanaspati, Lard and Tallow with standard productions ranging from 800 to 9.000 kg/h and pressures up to 100 bar.

FEATURES

| • |

Support structure made of stainless steel AISI 304 complete with protective casing. |

| • |

Crystallizer tubes scraped surface in high strength steel. |

| • |

AISI 316 stainless steel rotors complete with special steel tilting blades. |

| • |

Motor with flexible coupling transmission to the rotor. |

| • |

Chiller (installed inside the machine) complete with accessories. |

| • |

Electric control panel and control screen with PLC and PC. |

Note: All Coimix® machines are assembled in a single frame.

They are wired and tested in the E.B.M. premises prior delivery with their electric control panels.

PLASTICIZERS (PIN ROTORS)

The plasticizer is a machine that allows the best distribution of the crystals in the fat matrix making the final product more homogeneous and plastic. Varying the rotor speed it’s possible to achieve the desired consistency and texture. It’s equipped with a cooling circuit and / or independent heating and temperature-controlled depending from production process.

It can treat Table Margarine, Puff Pastry Margarine, Cake Margarine, Shortening, Ghee or Vanaspati, Lard / Tallow with standard productions ranging from 800 to 9.000 kg/h with pressures up to 100 bar.

FEATURES

| • |

Stainless steel AISI 304 and / or 316 for the parts in contact with the product |

| • |

Pinned tubes in stainless steel AISI 316. |

| • |

Pin rotors in AISI 316 stainless steel. |

| • |

Motor with flexible coupling transmission to the variable speed rotor. |

| • |

Homogenizer, where provided, in stainless steel AISI 316. |

| • |

Electric control panel and control with PLC and PC. |

Note: All Plasticizers are assembled in a single frame and are wired and tested in the E.B.M. premises prior delivery.

RESTING TUBE

The resting tube is an ancillary machine indicated for the intimate crystallization required by specific product such as margarine for puff pastry.

It is usually matched to a particular packaging system to obtain blocks and /or sheets of margarine

It features temperature control circuit for the best performance of the product and process, and has a modular structure.

FEATURES

| • |

Stainless steel AISI 304 and /or AISI 316 for the parts in contact with the product |

| • |

Product tube (modular) in stainless steel AISI 316 complete with special dies for the development of the crystal structure. |

| • |

Heating / cooling circuit to keep the product at correct process temperature. |

PRODUCT FILLING, WEIGHING AND PACKAGING SYSTE

Once the product (Margarine, Shortening, Ghee, Lard, etc.) from Coimix® has been crystallized it needs to be packed it for distribution to final customers.

E.B.M. produces various semiautomatic and automatic systems to package the product in the can and / or carton with inner plastic liner.

The weights can vary from 5 to 25 kg per piece.

FEATURES

| • |

Support structure made of stainless steel AISI 304 complete with protective casing. |

| • |

Dosing systems / weighing via pneumatic valves and load cells. |

| • |

Motorized steel rolls conveyor. |

| • |

Case erectors and automatic box loading systems |

| • |

Electric control panel and control with PLC and PC |

Note: All filling, weighing and packaging system are tested in E.B.M. premises before delivery

AUXILIARY SERVICES (Cooling groups, evaporative towers, Refrigerating systems, boilers, compressed air systems, etc..)

More and more customers are asking "turnkey" supplies with a single company in charge of all ancillaries needed for the production facility operation (Boilers, chillers, cooling towers, etc.).

E.B.M. is specialized in providing these ancillaries in cooperation with leading European manufacturers in order to provide the complete package to the customer.

FEATURES

| • |

Boiler for the supply of steam or hot water (60 and /or 90°C). |

| • |

Water cooling chillers (5 ÷ 15 ° C) |

| • |

Cooling towers for water at 25 ÷ 30 ° C |

| • |

Compressed air generators (5 ÷ 10 bar). |

| • |

Water treatment systems (industrial and potable) |

Note: All auxiliary services, are sized and designed by qualified engineers according European standards, certifications and compliance.