EUROPIAN BAKING MACHINE SRL ha ricevito:

Soggetto erogante : Agenzia delle Entrate

Data Incasso : 09/04/2021 – 24/06/2021

Motivazione: Contributo a fondo perduto DL 41/21 decreto sostegni)

EUROPIAN BAKING MACHINE SRL ha ricevito:

Soggetto erogante : Agenzia delle Entrate

Data Incasso : 09/04/2021 – 24/06/2021

Motivazione: Contributo a fondo perduto DL 41/21 decreto sostegni)

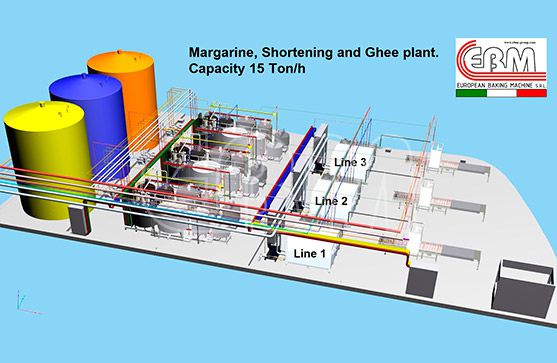

Contract signature for the supply of nr. 1 line for the production and packaging of Margarine and Shortening with capacity 10 Ton/h

We will present all our recent installations for:

1. MARGARINE, SHORTENING, GHEE, ANHYDROUS BUTTER, etc. (SSHE scraped surface heat exchanger, pin rotor, mixing system, high pressure pumps, packaging system, etc.).

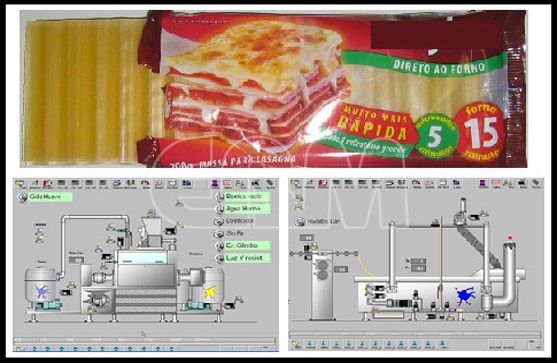

2. PASTA (Filled - Sheet - Cut / Long - Dry - Fresh), mixers, extrusion, pre-dryer shakers, dryer, pasteurizer with sprayed steam, water and / or steam cooker, etc.

We will present all our recent installations for:

1. MARGARINE, SHORTENING, GHEE, ANHYDROUS BUTTER, etc. (SSHE scraped surface heat exchanger, pin rotor, mixing system, high pressure pumps, packaging system, etc.).

2. PASTA (Filled - Sheet - Cut / Long - Dry - Fresh), mixers, extrusion, pre-dryer shakers, dryer, pasteurizer with sprayed steam, water and / or steam cooker, etc.

Come and visit us in Hall 5 at stand A5-11.

6 – 8 November, 2018 – Dubai, United Arab Emirates.

- We are waiting for you -

In the new issue of TecnAlimentaria, the Arab edition, there is the last interview made to our staff.

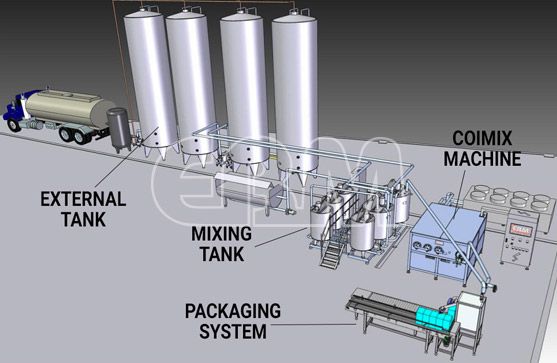

Technoloical data:

The line consists of:

• External tanks (heated and insulated) in stainless steel for oil storage

• Internal tanks for preparing recipes (oils + water + vitamins + additives + etc.).

• Coimix® (Scraped Surface Heat Exchanger) with laminators (Pin rotor).

• Finished product packaging system (bag in box or cups)

• 15 ° C storage cell packed product (complete with pallet racking)

• Heating systems (boiler, refrigeration units, etc.), water (evaporative towers, heating / cooling of drinking water), tires (compressed air generator).

The whole system was supplied simultaneously, installed and tested in one month.

Each line is composed of:

• Stainless steel external Tanks (heated and jacketed) for oil storage (common for the three lines).

• Internal Tanks for preparing recipes (Oil + Water + Vitamins + additives + etc.).

• Coimix® (Scraped Surface Heat Exchanger) with plasticizers (Pin rotor).

• Packaging system of finished product (bag in box)

• Storage cell at 15°C for packaged product (complete with pallets, doors and shelving)

• Heating equipment (boilers, chillers, etc.), Water (cooling towers, heating / cooling of potable water), pneumatic (air compressor).

The three lines were provided simultaneously, installed and tested in three months.

The line consists of:

• Automatic continue press under total vacuum

• Pasta sheet calibration and gauging system

• Water cooker

• Tiered continuous dryer by catalytic plates(300 ÷ 400°C).

• Dry lasagna cutting system.

• Counting system for lasagna sheet number per package.

• Lasagna cooler before packaging.

• Electrical control panels with PLC and PC

The system has been installed and tested in two months.

The plant is composed of:

• Stainless steel external Tanks(heated and jacketed) for oil storage.

• Internal Tanks for preparing recipes (Oil + Water + Vitamins + additives + etc.).

• Coimix® (Scraped Surface Heat Exchanger) with plasticizer (Pin rotor).

• Packaging system of finished product (bag in box)

• Storage cell at 15°C for packaged product (complete with pallets, doors and shelving)

• Heating equipment (boilers, chillers, etc.), Water (cooling towers, heating / cooling of potable water), pneumatic (air compressor).

The system has been installed and tested in two months.