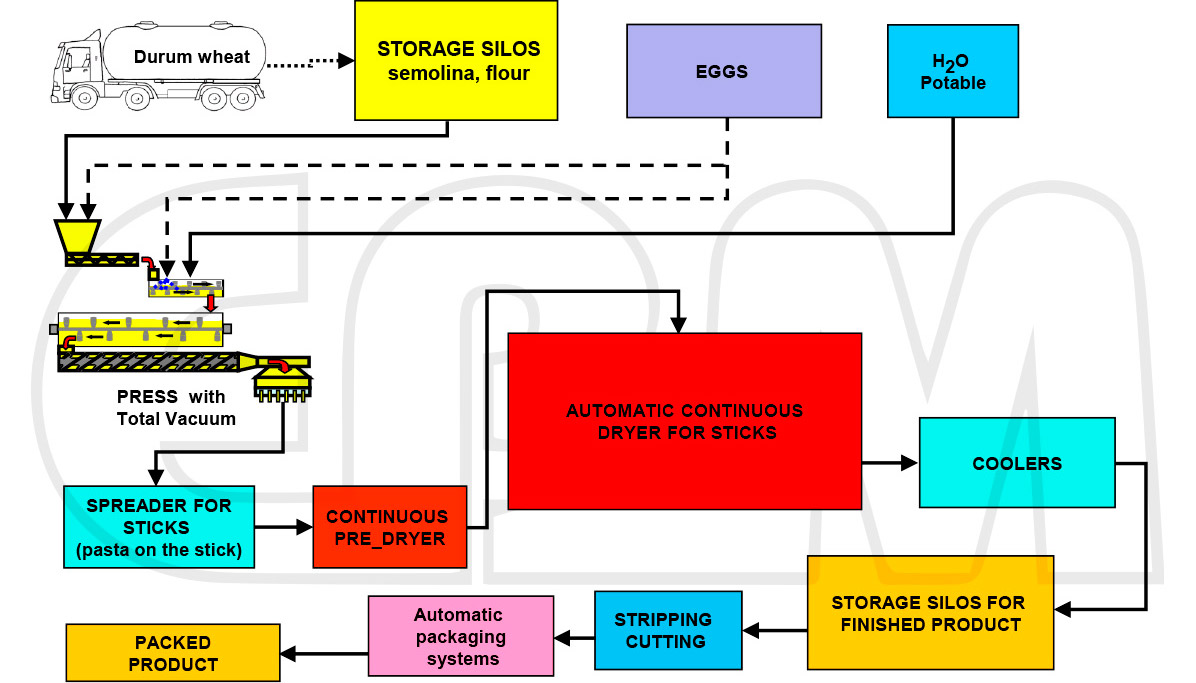

The most common name for cataloging the long cut dry pasta is "Spaghetti". These are obtained by mixing flour and water in order to obtain a dough which is extruded through dies of different size and cut. The sizes and shapes are different and depend on the type of extruder (Spaghetti, Linguine, Angel hairs, etc.).

Once formed, the product will undergo a heat treatment (drying) in order to reduce its moisture to obtain a stable product with a long shelf-life and suitable to be packaged.

EBM is able to provide all the equipment for the entire production cycle, starting from the storage of raw materials, semi-automatic lines (with cabin drying) or automatic (continuous belt dryers) to produce dry short pasta, to storage silos (finished product storage) and dry product packaging systems.

Supplies may also be of individual machines or complete "turnkey" plants.

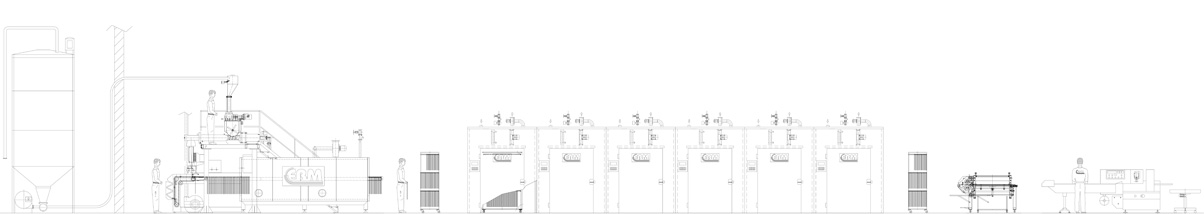

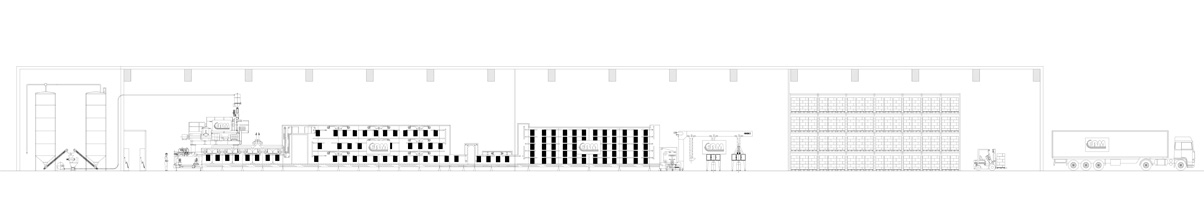

AUTOMATIC CONTINUOUS PRESS

+ SPREADER FOR STICK

(Pressa automatica +

Stenditore automatico per canne)

AUTOMATIC CONTINUOUS PRE-DRYER

(Pre-essicatoio continuo)

DRY CELL

(Celle di essicazione statica)

TROLLEYS FOR STICKS

WITH SPAGHETTI

(Carrelli porta canne con spaghetti)

SPREADER FOR STICK

(Stenditore automatico per canne)

SPREADER FOR STICK

(Stenditore automatico per canne)

SPREADER FOR STICK

(Stenditore automatico per canne)

CONTINUOUS DRYER

(Essicatoio continuo)