The term "Puff pastry margarine" means margarine (like "water in oil" emulsions) which is normally dedicated to the pastry industry.

Its characteristic is linked to higher plasticity and ability to make the products crispier, soft and easy be laminated and with good performance in baking.

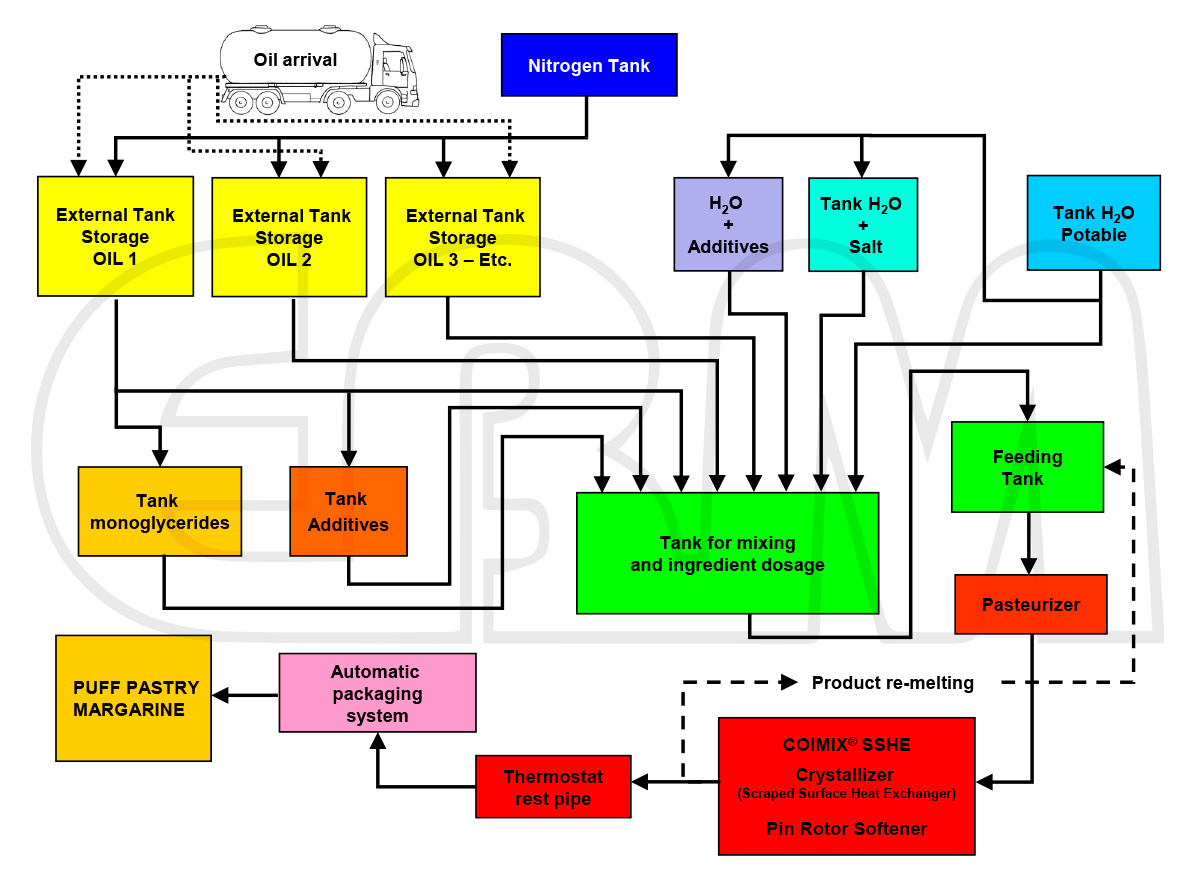

EBM is able to provide all the equipment for the entire production cycle starting from the oil storage tank, the mixing systems for raw materials (Mixing tank), the COIMIX® machine (SSHE - Scraped Surface Heat Exchanger), the plasticizer (Pin Rotor), the aging pipe (resting tube) up to the packaging systems of the finished product.

Supplies may be of individual machines or complete "turnkey" plants.

EXTERNAL OIL STORAGE TANK

MIXING & DOSING TANK + PASTEURIZER

COIMIX® HP mod. 32W (SSHE)